How to choose the right brush?

The choice of the brush depends largely on the type of material to be brushed. In the case of machine-operated brushes, it is necessary to know the characteristics of the machine on which the brush is to be fixed and the finish to be obtained:

1.

Material to be treated

Carbon steel

Among the main characteristics of carbon steel we can highlight its great resistance and hardness. For this reason it is advisable to use brushes with carbon steel wire.

Wood

Although there are many types of wood, the resistance in its manipulation will be determined by the structure of its grain. There is no single criterion for the choice of a planer, but the use of steel wire or abrasive nylon is recommended.

Stainless steel

Stainless steel provides corrosion resistance and durability. To maintain these properties it is advisable to use brushes with stainless steel wire.

Aluminum

Aluminum is a light material and very resistant to corrosion, so it is advisable to use brushes with stainless steel wire.

Other surfaces

Among the main characteristics of carbon steel we can highlight its great resistance and hardness. For this reason it is advisable to use brushes with carbon steel wire.

How to choose the right brush?

Depending on the type of machine to be used for the development of the activity, the following characteristics must be taken into account:

► Maximum allowable diameter

► Rotational speed (R.P.M) = Peripheral speed.

► Shaft characteristics (diameter or thread type: M14, 5/8″).

2.

Tool to use

En función del tipo de maquina que tengamos que utilizar para el desarrollo de la actividad, deberemos tener en cuenta las siguientes características:

► Maximum allowable diameter

► Rotational speed (R.P.M) = Peripheral speed.

► Shaft characteristics (diameter or thread type: M14, 5/8″).

| Tool | RPM | Most common brushes | Model | ø Brush | ||

| Fixed Bench Grinders | 1.500 - 3.000 | Circular, Crimped and Braided | F-15, F-23, F-18, F-16 y F- 17 | Between 75 mm (3") and 350 mm (14") | |

| Angle Grinder | 5.000 - 8.500 | Circular, Wavy and Braided. Wavy Cup, Braided Cup, Nylon Cup, Cable Cup, Cable Cup | F-15, F-18, F-24, F-25, F-17 y F-16 -26 | Between 100 mm (4") and 175 mm (7"). Between 80 mm (3.1/4") and 150 mm (6"). | |

| Mini Angle Grinder | 10.000 - 13.000 | High Revolutions, Tumbler, Cup, Cone and Flat Models | LAR24, LARCO, LARPO, LAR25, LARCR, LARPR | Between 65 mm (2.3/4") and 125 mm (5") | |

| Rotalin | 15.000 - 20.000 | Circular and Industrial Brushes with shank | F-21, F-22, BT | Between 12 mm (1/2") and 100 mm (4") | |

| Drill | 4500 | Circular and Industrial Brushes with shank | BR, BO, FBE, FTA, FBR, BE, TA Y TAT | Between 22 mm (1") and 100 mm (4") | |

How to choose the right brush?

The finish that we will achieve in our work will be determined by the following variables:

3.1 Type of wire and nylon

3.2 Wire form

3.3 Barbed protrusion

3.4 Wire thickness

3.

Desired finish

The finish that we will achieve in our work will be determined by the following variables:

3.1 Types of wire and Nylon

| Material | Cod | ø mm | ø / " | Tensile strength | Carbon content | Features | |

| Stainless Steel | BE BG B BK | 0,20 0,30 0,40 0,50 | .008" .012" .016" .020" | 160 - 180 kg/mm² | <0.030% | According to AISI304-L and AISI 302 standards. For brushing on stainless steel, aluminum or non-ferrous metals. Slightly magnetic |

| Brass-plated steel Monofilament | CD CE CF CG CI CK | 0,15 0,20 0,25 0,30 0,40 0,50 | .006" .008" .010" .012" .016" .020" | 240 -260 kg/mm² | 0,75% | Flexibility and high performance. Protected against oxidation. Not suitable for stainless steel surfaces. Wide range of finishes. |

| Steel | EH EI EK EL EQ | 0,35 0,40 0,50 0,60 0,80 | .014" .016" .020" .023" .032" | 180 - 200 kg/mm² | 0,50-0,60% | High starting capacity. Suitable for braided brushes. Not suitable for stainless steel surfaces. |

| Brass | HG HI | 0,30 0,40 | .012" .016" | 80-95 kg/mm² | It does not produce sparks. Suitable for fine finishes on non-ferrous materials. | |

| Wire Rope Wire Rope Steel Brass | CEA | 2+2 x 0,32 | 12 x .009" | 240-260 kg/mm² | 0,75% | Flexible, compact, aggressive |

| Abrasive Nylon Grain 46 NAU | NA RED BLUE | 180 80 150 | High flexibility. Access to irregular areas. Suitable for cleaning and polishing wood and metal surfaces. Does not scratch the surface. |

3.2 Wire form

Wavy: Due to their greater flexibility, they are suitable for working on irregular surfaces and offer a more regular and fine finish.

Braided: It gives the brush a longer life and high starting capacity, but a coarser finish.

Cable: These are crimped wires formed by several wires. These cables are made up of a group of high-strength steel wires that form a flexible, compact and aggressive unit, offering an average type finish.

3.3 Tine overhang

A long tine overhang results in a flexible brush, resulting in a uniform effect, even on uneven surfaces. A smaller tine overhang results in a higher stock removal rate.

3.4 Wire thickness

The diameter of the wire affects the type of finish obtained. The thicker the wire, the coarser the brushing and the higher the stock removal. A fine wire gives a smoother finish.

SAFETY WARNINGS

In accordance with the contents of the European Standard

EN 1083-2 on Safety requirements for use

of wire brushes as machine accessories,

we require you to comply with the following

instructions for use:

- Always wear protective goggles, appropriate clothing and equipment.

- Do not use the brushes in machines whose speeds

are higher than the maximum R.P.M. of the brush. - Do not remove any protection from the machine.

- Do not use deteriorated brushes. Oxidation or any other chemical alteration in the wire can affect brush performance. Keep brushes stored in racks, containers or boxes, so that they are protected from environmental effects (humidity, acids, gases, etc).

RECOMMENDATIONS USE

- Check before use that the brush is not damaged.

- Caution during assembly. Follow the indicated instructions for use with extreme care.

- The brushing work has to be carried out by the wire tips.

- The advantage of brushes over abrasives is that, due to the flexibility of the wire, they adapt more easily to irregular surfaces.

- Excessive pressure on the brush can cause an over-bending effect on the wires, increasing their fatigue, causing premature breakage and therefore a considerable reduction in their service life.

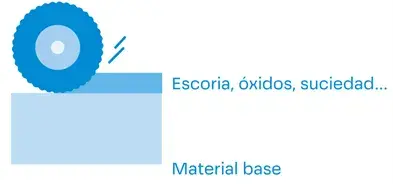

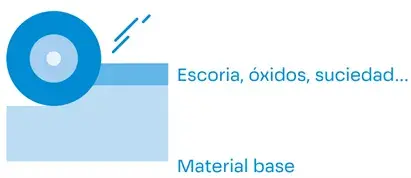

Metal brushes

DO NOT WEAR the base material

Hard abrasive tools

DESGASTAN a certain amount of base material.

PROBLEM

RECOMMENDED SOLUTIONS

Brushing is excessively aggressive

- Choosing a brush with a thinner wire

- Choose a brush with longer trim length

- Working at lower speed

Brushing is not aggressive enough

- Choosing a brush with thicker wire

- Choose a brush with a smaller overhang of tines

- Working at higher speed

The brush does not remove the burrs, but flattens and polishes them.

- Choosing a brush with thicker wire

- Choose a brush with a smaller overhang of tines

- Working at higher speed

The finish has to be finer

- Choosing a brush with a thinner wire

- Choose a brush with longer trim length

- Choosing an Abrasive Nylon Brush

Brushing is not uniform

- Reduce brushing pressure

- Automate operations to avoid human variability

PROBLEM

RECOMMENDED SOLUTIONS

Brushing is excessively aggressive

- Choosing a brush with a thinner wire

- Choose a brush with longer trim length

- Working at lower speed

Brushing is not aggressive enough

- Choosing a brush with thicker wire

- Choose a brush with a smaller overhang of tines

- Working at higher speed

The brush does not remove the burrs, but flattens and polishes them.

- Choosing a brush with thicker wire

- Choose a brush with a smaller overhang of tines

- Working at higher speed

The finish has to be finer

- Choosing a brush with a thinner wire

- Choose a brush with longer trim length

- Choosing an Abrasive Nylon Brush

Brushing is not uniform

- Reduce brushing pressure

- Automate operations to avoid human variability

NEW IMAGE

The new image of the FECIN brushes is aimed at improving the identification of the type of brush to be used. By means of the colored rings, we can differentiate the types of materials available.

Red: Steel

Blue: Stainless Steel

Green: Brass

Orange: Nylon

▶ Colored ring, facilitates identification of wire type.

▶ Clearer brush information.

New cup color.

▶ Professional quality.